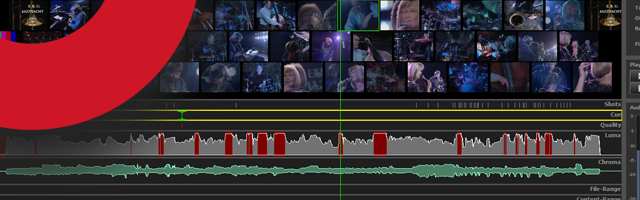

NOA’s workflows address this by embedding quality control directly into the digitization process. Instead of treating QC as an asynchronous activity, checks are performed continuously using electrical measurements and algorithmic analysis. Signal integrity, stability, and anomalies are evaluated objectively while the work is being done.

This shifts the role of staff significantly. Operators are no longer expected to hunt for issues across endless files and timelines. The system flags deviations early and clearly, highlighting where attention is actually required. Time is spent resolving real problems, not searching for potential ones.

At scale, this approach is essential. Manual review alone does not scale linearly with throughput. Automated analysis does. Reporting is consistent, repeatable, and defensible, which is critical for long-term preservation projects and institutional accountability.

The result is predictable quality even under high daily workloads. Teams maintain control without burnout, management gains visibility, and collections are digitized with confidence rather than hope. Quality control becomes a system property, not a heroic effort.